Our ESG Strategy

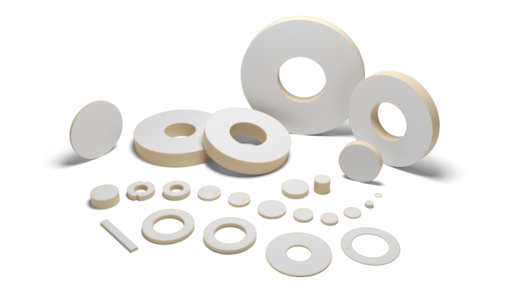

At CeramTec, we are committed to producing high-quality technical ceramics in a sustainable way. We recognise the environmental challenges for our industry and take responsibility for minimising our impact while delivering products that support a sustainable future.

Producing technical ceramics requires significant energy, a reality we are continually addressing through innovative measures. While energy-intensive, our production processes result in highly durable components, which means that our industrial products require less frequent replacement, contributing to lower environmental impact over their lifetime. These material characteristics make CeramTec products more sustainable for critical applications, contributing to the reduction of waste, and supporting health-focused industries.

Our Ambitions

We are actively researching innovative ways to decarbonise and reduce our energy consumption. While we are proud of our efforts, we recognise there is much more to achieve.

Our actions:

Numerous operational activities and investments have been made to reduce energy consumption in daily operations and to lower emissions resulting from our direct business processes. Some examples are listed below:

- Ongoing installation of photovoltaic (PV) panels

- Purchase Power Agreement for 10 GWh of electricity produced by German PV park

- Purchase of certificates of origin for renewable electricity

- CO2 neutral electricity procurement strategy

- Development of a decarbonisation roadmap

- Green electricity by 2030

We have already implemented various measures to reduce our carbon footprint and are continuously discussing further actions, including energy efficiency measures, the use of renewable energy, switching to renewable fuels, and training our employees to handle resources responsibly. Our employees are encouraged to submit their ideas for emissions reductions, with regular surveys conducted.

One of our recent milestones on our decarbonisation pathway is the closing of a Power Purchase Agreement (PPA) in 2023. Through this, we source a portion of our electricity consumption from verifiable renewable sources in Germany.

Many of CeramTec's sites already have photovoltaic systems in operation, ensuring local sourcing of renewable energy. Other plants, such as those in our UK portfolio, are fully supplied with green electricity through 100% green electricity Renewable Energy Certificates (REC), which have been in place since October 2023.

We are already benefiting from projects initiated in recent years, such as our investment in waste heat recovery. We also continue to focus on energy efficiency, investing in LED lighting and other improvements in our buildings. We are also enabling the transfer to fleets with more electric vehicles (EV), for example by introducing EV charging stations on site, with all our German sites now fully equipped.

To demonstrate our commitment to climate change, we have launched a decarbonization project in 2024 with the aim of designing robust roadmaps and achieving long-term effects in climate protection.

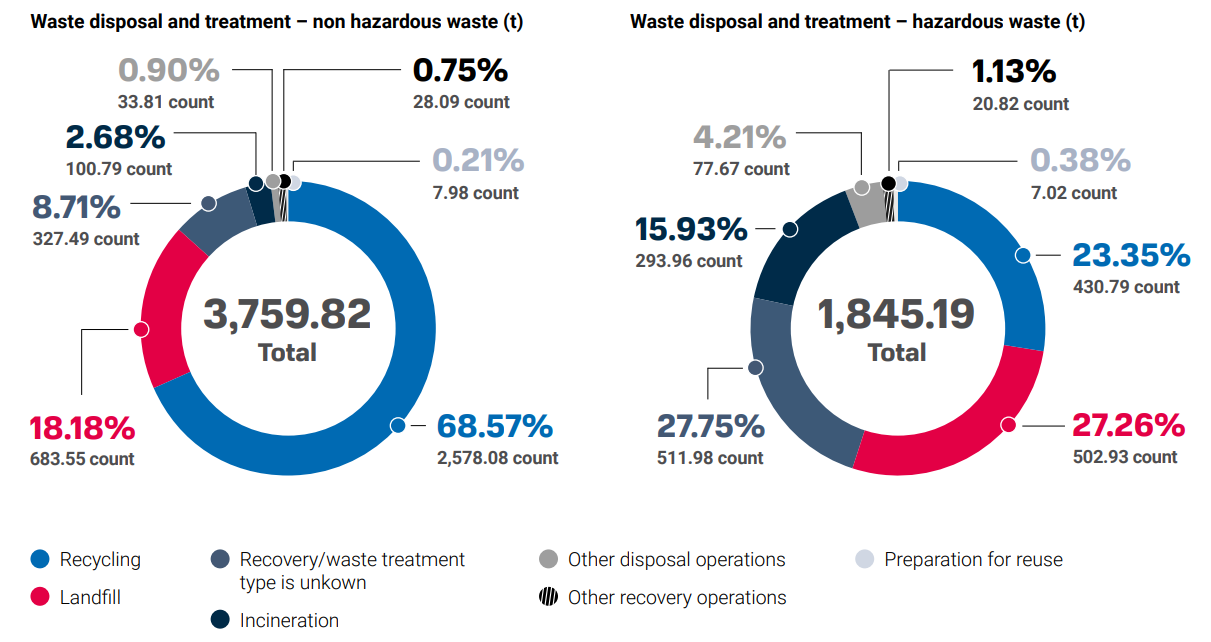

At CeramTec, our operations are largely focused on production, so circular economy and all of its components are of very high importance to our sustainability strategy.

Our actions:

Where possible, we resell our waste products to be recycled or repurposed. A portion of our ceramics waste is utilised by other companies, while some metals are sold to specialized waste companies.

Through proactive management and continued compliance with regulatory standards, we intend to promote a cleaner, healthier environment through pollution reduction.

Our actions:

Each of our sites operates a variety of air filters, thermal upgrades, cooling towers and wastewater treatment systems. All sites, including those without ISO certification, comply with the respective national legislation regarding pollution limits.

Our ISO 14001-certified sites at CeramTec GmbH (Plochingen, Ebersbach Marktredwitz and Lauf, all Germany), Czech Republic, UK, and China, have emergency management systems in place, including procedures to ensure preparedness for incidents also involving hazardous substances. These substances are stored in compliance with applicable legal requirements.

None of our operations would be possible without the efforts and commitment of our workforce. The health and well-being of our people is a priority for us, and we continue to introduce policies and initiatives to support this objective.

All employees are provided with the appropriate personal protective equipment (PPE) as required for their role. CeramTec also operates a portal through which our employees can report ‘near misses’ in the workplace.

Besides Health & Safety at work we offer a great variety of healthcare services to our staff.

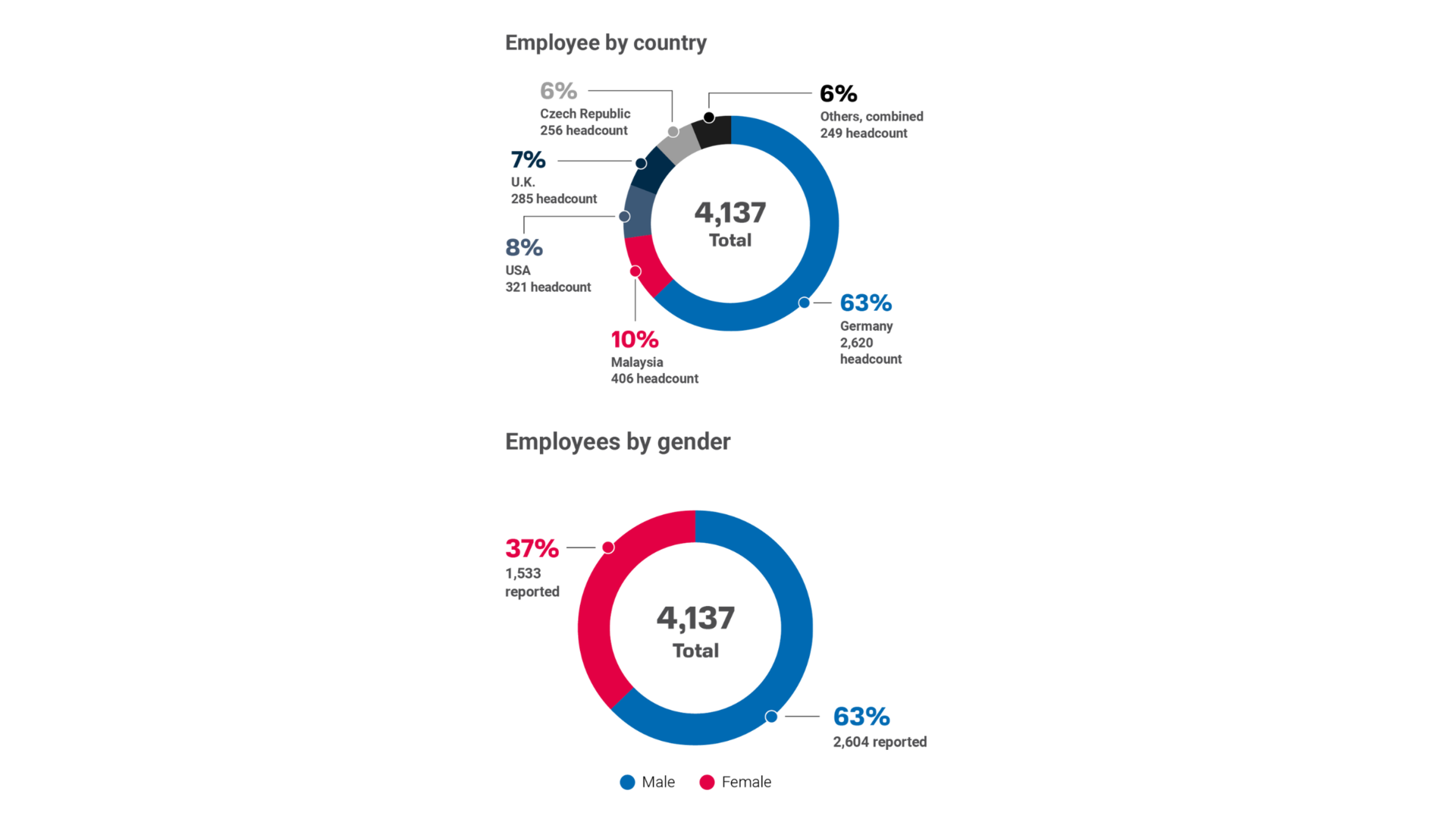

Our management training emphasises diversity, with regular workshops for managers and HR to foster inclusive personnel selection and promote women in leadership through awareness and effective training. This approach includes support from Konzernschwerbehindertenvertretung (KSBV), a body representing disabled employees.

CeramTec uses its intranet and CT Inside app (available in Germany) to share news, and recently piloted an employee survey in Germany, with plans to expand it globally in 2025. Key initiatives include equipping management with sensitive communication tools, holding HR updates and engagement circles with leaders, and hosting inclusive events like “popup dinners” with the board members. Additionally, idea management programs encourage employee suggestions for improvement.

We conduct our business in a manner that respects the human rights and dignity of all, and we support international efforts to promote and protect human rights, including the absolute rejection to child labour, slavery, human trafficking and forced labour. These efforts are led by our Human Rights Officer and supported by our entire organisation.

We encourage our employees and other stakeholders to report concerns by providing means to contact us confidentially. To that end we have a dedicated hotline, EthicsPoint, which enables also anonymous reports. In the reporting year, there were no fines or penalties issued by any authorities, or compensation for damages paid by the Company based on incidents and complaints. No severe human rights incidents were reported.

“Learn and Grow” is one of CeramTec's corporate values. Continuous learning and development are a central aspect of not only our sustainability strategy, but also our business outlook. Our "Training and Competences" process instruction—applicable to our CT GmbH Industrial, Service Centre, and ETEC divisions—defines the structured approach to training within the organisation.

All high-risk suppliers[1] have been requested to complete an ESG assessment

- Percentage of high-risk suppliers that have undergone an ESG assessment

- Percentage of suppliers rated as high risk

All top suppliers[2] have been requested to complete an ESG assessment

- Percentage of top suppliers that have undergone an ESG assessment

All suppliers undergo an ESG pre-risk check

- Number of top suppliers audited with on-site audit or third-party audit

Cultivate and strengthen partnerships with suppliers for a more sustainable and responsible supply chain

- Dialogue with suppliers, site visits, and renewed contracts

- Review of supplier code of conduct

- Implement new supplier code of conduct

- Online ESG risk assessment for suppliers

- Online ESG self-assessment for suppliers

- Further action based on risk assessment results

[1] High-risk suppliers: all suppliers that are rated as high-risk after an internal ESG risk assessment based on a variety of ESG indices.

[2] Top suppliers: Top 50 suppliers in spend, make up ~ 60% of spend.

- Review of supplier code of conduct

- Implement new supplier code of conduct

- Online ESG risk assessment for Suppliers

- Online ESG self-assessment for suppliers

- Further action based on risk assessment results

- Supply Chain Act (to date only in German)

- AEO: Authorized Economic Operator: signifies that abusiness is recognised as a reliable and secure player in the global supply chain, facilitating streamlined customs processes and international trade.

- IATF 16949: a global standard for quality management in the automotive industry, focusing on defect prevention, reducing variation, and promoting continuous improvement throughout the supply chain.

Products

We focus on:

- Delivering best-in-class quality across our product offerings.

- Developing technical ceramics that aid the sustainability transformation of our industry customers, especially in areas such as electrification and smart grid technology.

- Offering durable, biocompatible implant components that enhance the well-being of patients.

Governance

Our governance approach ensures we are creating an inclusive and ethical environment for our people and those whom we do business. For CeramTec, this means applying meaningful governance structures and following best practices when it comes to reporting misconduct, employee recognition, and health and safety.

Find out more in the Compliance section.

The CeramTec Supervisory Board is comprised of both employer and employee members, in equal measure. They are given regular compliance training by the Chief Compliance Officer (CCO). The Advisory Committee which represents CeramTec shareholders is also regularly updated on CeramTec compliance matters.

- Our Code of Conduct reflects our commitment to transparency and trust and lays out the various ways that our staff and third parties can report any concerns around how we conduct our business. Our Code of Conduct encourages strength through integrity and is available on our website. Our CeramTec Group Supplier Standards are publicly available and detail our expectations for our suppliers.

- If any team member is not comfortable with the reporting options available, they can report anonymously through ‘EthicsPoint’, a third party managed reporting tool. EthicsPoint offers online and telephone reporting, with translators, and is available 24/7. Any report received within CeramTec is managed appropriately, and in accordance with our guidelines. CeramTec has a non-retaliation policy for any whistleblowers whoreport or ask questions in good faith and our system is designed to protect the anonymity of those reporting, if they so elect.

At CeramTec, we take data privacy and security very seriously and to this end, all of our German colleagues are trained on the German data protection law as well as on cyber security risks and respective protective measures. Regular penetration tests are conducted to identify vulnerabilities, and our German sites maintain TISAX compliance, reflecting our commitment to stringent industry standards.