Technical Ceramics - Material of the Future

Technical ceramics are undoubtedly a unique material. Its outstanding material properties enable applications that were previously unthinkable. Whether in medical technology, mobility & e-mobility, cutting tools, electrical engineering & electronics or industry - technical ceramics offer a wide range of benefits and applications.

With technical ceramics, we develop innovative and high-performance products & solutions together with our customers that help shape the world of tomorrow. Thanks to their extreme hardness, resistance to high temperatures, chemicals and wear, as well as their excellent electrical properties, technical ceramics are able to create particularly high-performance and durable products. Therefore, we can justifiably claim: We live ceramics!

- Also discover: Materials in comparison - advantages of technical ceramics over metals and plastics.

Fascination of Advanced Ceramics

Let us inspire you with the fascinating possibilities of high-performance ceramics!

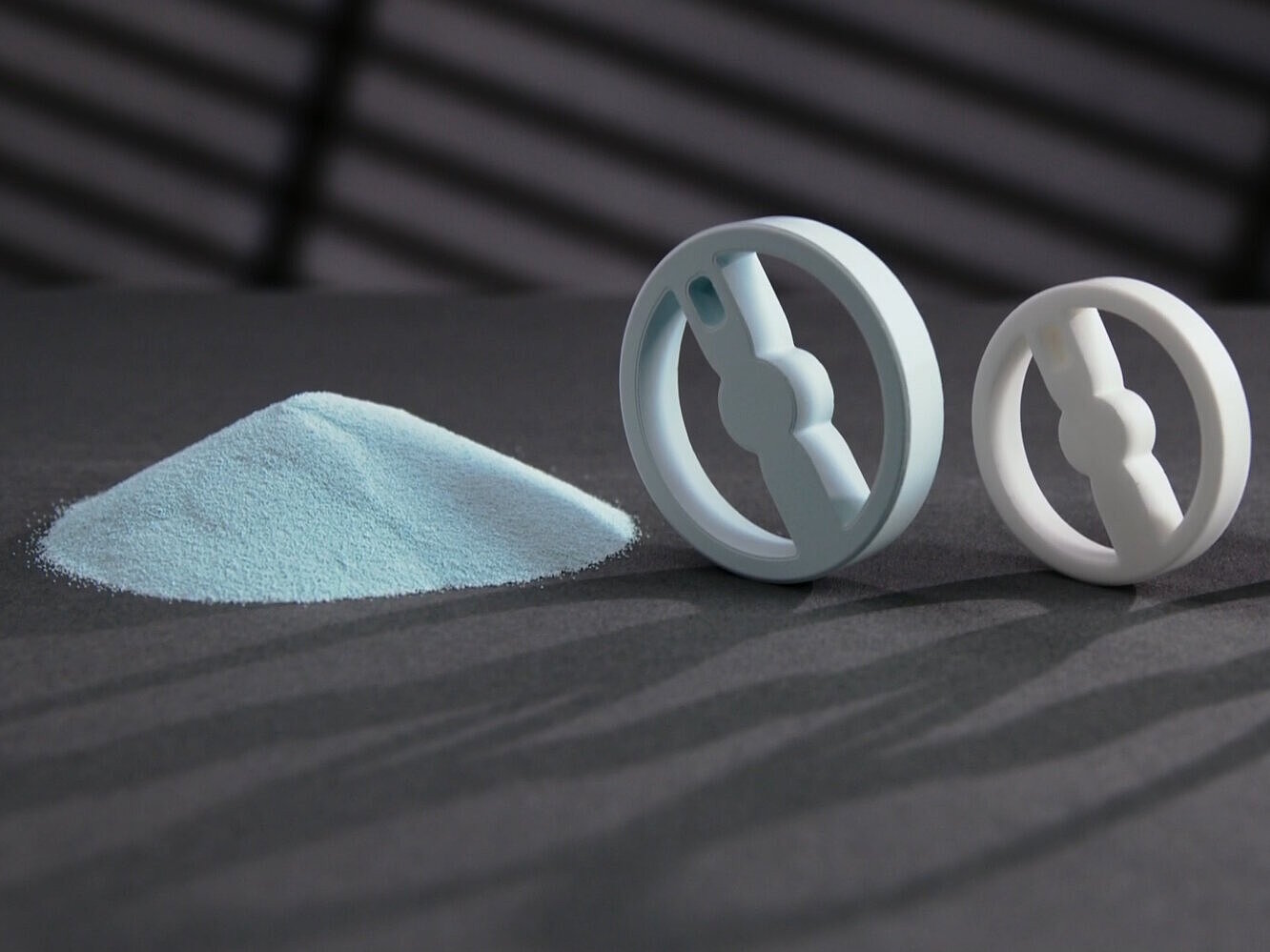

Immerse yourself with us in the production of this material of the future - from its origins in the form of silicates and metallic compounds in the earth to specialised high-end solutions for the challenges of the future.

The basis of all CeramTec products is high-performance ceramics. It is also known as technical ceramics, engineering ceramics or industrial ceramics. Behind this lies a multitude of different, in part highly specialised ceramic materials with unique mechanical, thermal, biochemical and electrical properties - as well as their combinations.

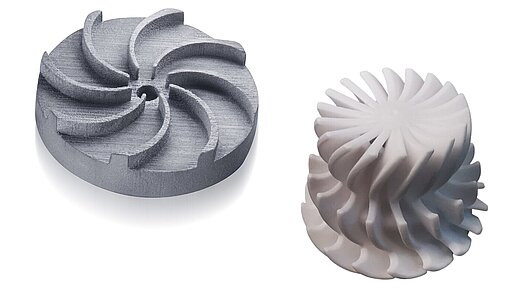

These properties can be further developed, optimised and combined for use in technical applications. Technical ceramics can thus be used to design very high-performance components that optimally fulfil their task and can be far superior to competing materials such as metal or plastic in their field of application - because technical ceramics are wear-resistant, chemically corrosion-resistant, have a low density and are temperature-resistant.

Material Groups

CeramTec technical ceramics can be divided into four major groups of ceramic materials: Silicate ceramics, oxide ceramics, non-oxide ceramics and piezoceramics.

Silicate ceramics are the oldest representative of ceramic materials for technical applications and consist mainly of naturally occurring raw materials in combination with aluminium oxide (alumina, aluminium silicates). The oxide ceramics group includes materials that essentially consist of metal oxides, such as aluminum oxide, zirconium oxide, aluminum titanate or dispersion ceramics.

The material group non-oxide ceramics includes ceramic materials based on compounds of carbon, nitrogen and silicon, such as silicon carbide, silicon nitride or aluminum nitride. Piezoceramics (also: functional ceramics) are ceramic materials that serve to convert mechanical variables into electrical variables, or vice versa, electrical signals into mechanical movements or vibrations.

Competences & Expertise

We have been a leading developer, manufacturer and global provider of special solutions made of advanced ceramics since 1903. Hip prostheses, dental implants, applications in the mobility and electronics industry or in aerospace - advanced ceramics from CeramTec are used in numerous areas. Our portfolio includes well over 10,000 different products, parts and components made of technical ceramics as well as a variety of ceramic materials.

We employ around 3,800 people in Europe, the USA and Asia - more than 2,000 of them at locations in Germany. Our order books are more than full. That is why we are continuously investing in Germany and worldwide.

Development of innovative products, materials and processing technologies

We continuously research and develop materials as well as manufacturing and coating processes for new products in established and in new markets. Our product development focuses primarily on providing forward-looking customer-oriented innovations and solutions.

Our centralised R&D infrastructure, with over 600 patents and more than 150 scientists and engineers working in state-of-the-art laboratory facilities and collaborating with leading research institutions worldwide, enables us to remain an innovation driver.

Cutting Tools

For more than 60 years, the CeramTec brand SPK® has stood for high-performance and efficient machining processes with ceramic cutting materials, PcBN grades and cermets. The CeramTec SPK® Solution Team creates practical solutions in vehicle construction, aerospace, the gear and bearing industry, mechanical engineering and wind energy.

Electronic Applications

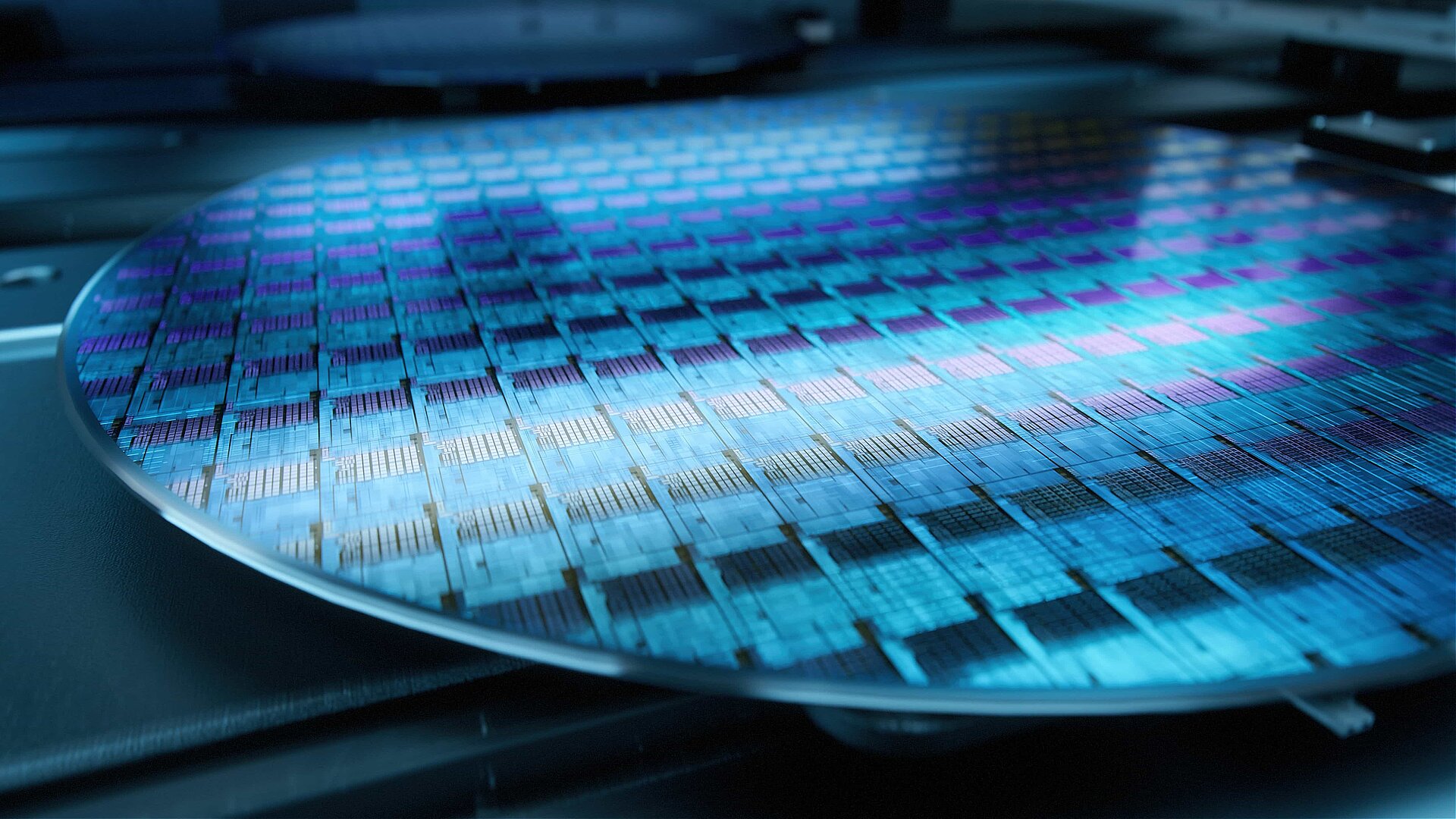

Technical ceramics are widely used in electronics and electrical engineering as well as in information and communication technology. Technical ceramics are used in a variety of applications such as circuit carriers, core materials, protective components, actuators and sensors.

Experience Technical Ceramics

If you would like to familiarise yourself with technical ceramics and its possibilities, we recommend first and foremost our "Technical Ceramics Handbook" and the brochure "Advanced Ceramics in Our World" in the download area.

In addition, you will encounter technical ceramics at many international trade fairs and events - but a visit to the Technical Ceramics exhibition at the Deutsches Museum in Munich or the Porzellanikon, the European Museum of Technical Ceramics in Selb, is always worthwhile. CeramTec contributed numerous exhibits made of ceramic materials to both exhibitions.

We also recommend reading the article about advanced ceramics on Wikipedia and visiting the web pages of the Ceramics Industry Association, were you will find specific information.