Materials in Comparison

Compared to metals, technical ceramics are characterised by extreme heat and corrosion resistance, making them ideal for demanding high-temperature applications. Unlike plastics, technical ceramics also offer unsurpassed hardness, wear resistance and excellent electrical insulation properties. Their low weight enables efficiency improvements in numerous industries.

Discover with us one of the most impressive materials of our time - technical ceramics.

Thermal Management

When it comes to the transfer of heat and electrical insulation is required at the same time, some technical ceramics are hard to beat as materials. In addition, there are technical ceramics with very low thermal conductivity and at the same time low thermal expansion, which are excellently suited where heat is not to be transferred. Last but not least, unlike many metals and plastics, technical ceramics retain their strength and stability even at high temperatures.

Technical ceramics thus pave the way for effective heat and energy management. It is revolutionising entire industries and has already become indispensable in numerous applications, from high-temperature furnaces and electronics to thermal insulation in spacecraft.

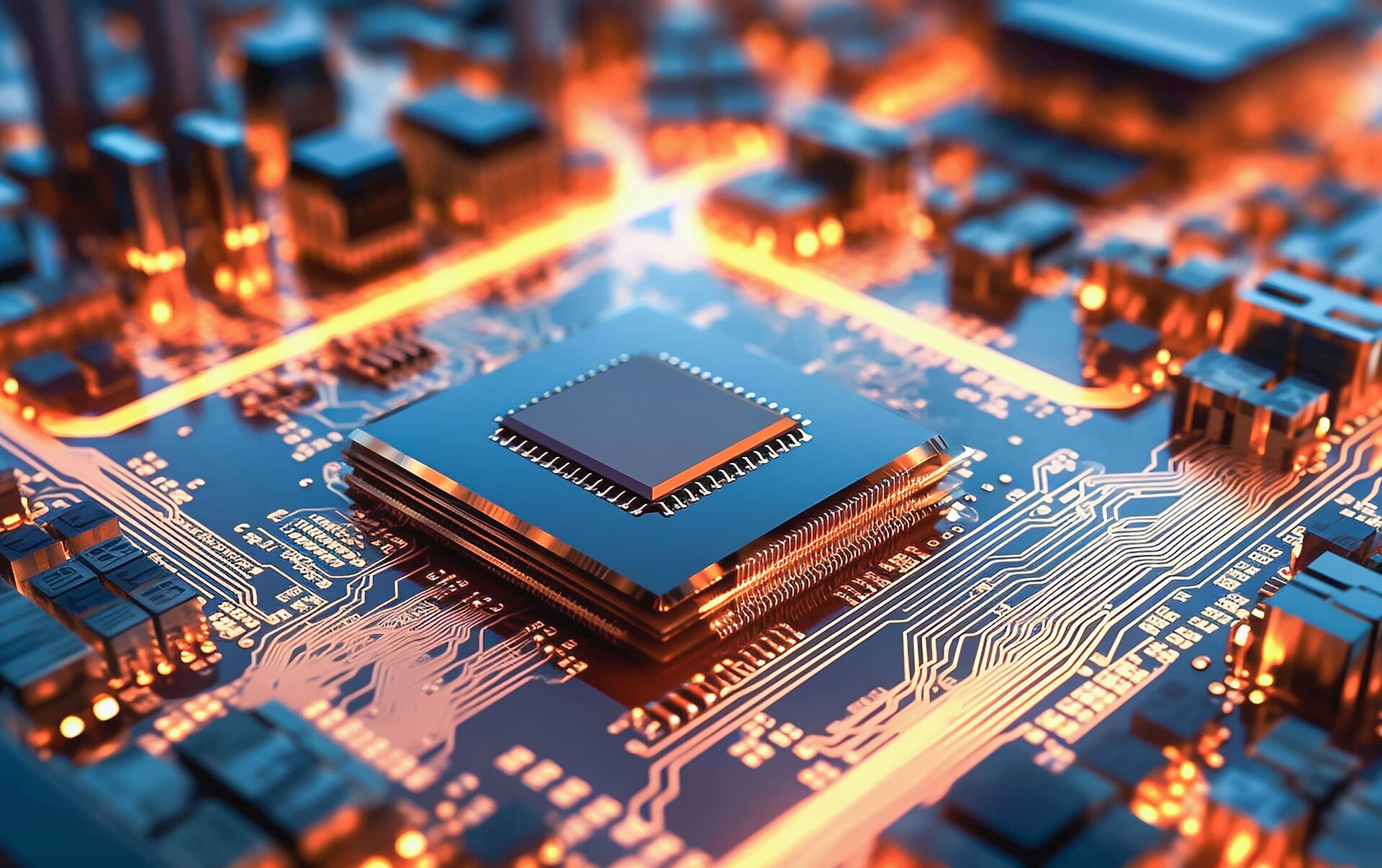

Electrical Insulation - Dielectric Strength

Unlike metals, technical ceramics have exceptional insulating properties that can withstand extreme voltages and temperatures without sacrificing performance. On the other hand, certain compositions can also provide selective conductivity. Compared to plastics, technical ceramics also exhibit remarkable resistance to temperature fluctuations and chemicals without sacrificing stability.

These properties make technical ceramics the preferred choice for demanding applications, such as high-voltage technology or electronics.

Waterproof & Corrosion Resistant

While metals corrode over time, technical ceramics retain their exceptional corrosion resistance - whether in the chemical industry, in (pipe) lines or in containers with corrosive substances. Unlike plastics, which are often susceptible to moisture penetration, technical ceramics remain watertight even under extreme pressure conditions in applications such as underwater technologies or medical devices.

Due to its unique composition and structure, technical ceramics set standards in terms of corrosion resistance, impermeability and durability.

Chemical Resistance

In the chemical industry, where aggressive acids or alkalis are used in many processes, the resistance of technical ceramics to metals, which are often exposed to rust and erosion under corrosive conditions, is particularly convincing. In the semiconductor industry, ceramic components are invaluable due to their insensitivity to etching processes and extreme temperatures.

Plastics often swell, decompose or lose their mechanical properties when in contact with chemicals - not so technical ceramics. It retains its structure and strength and is therefore often used in the food and pharmaceutical industries, where hygienic conditions and chemical cleaning processes play an important role.

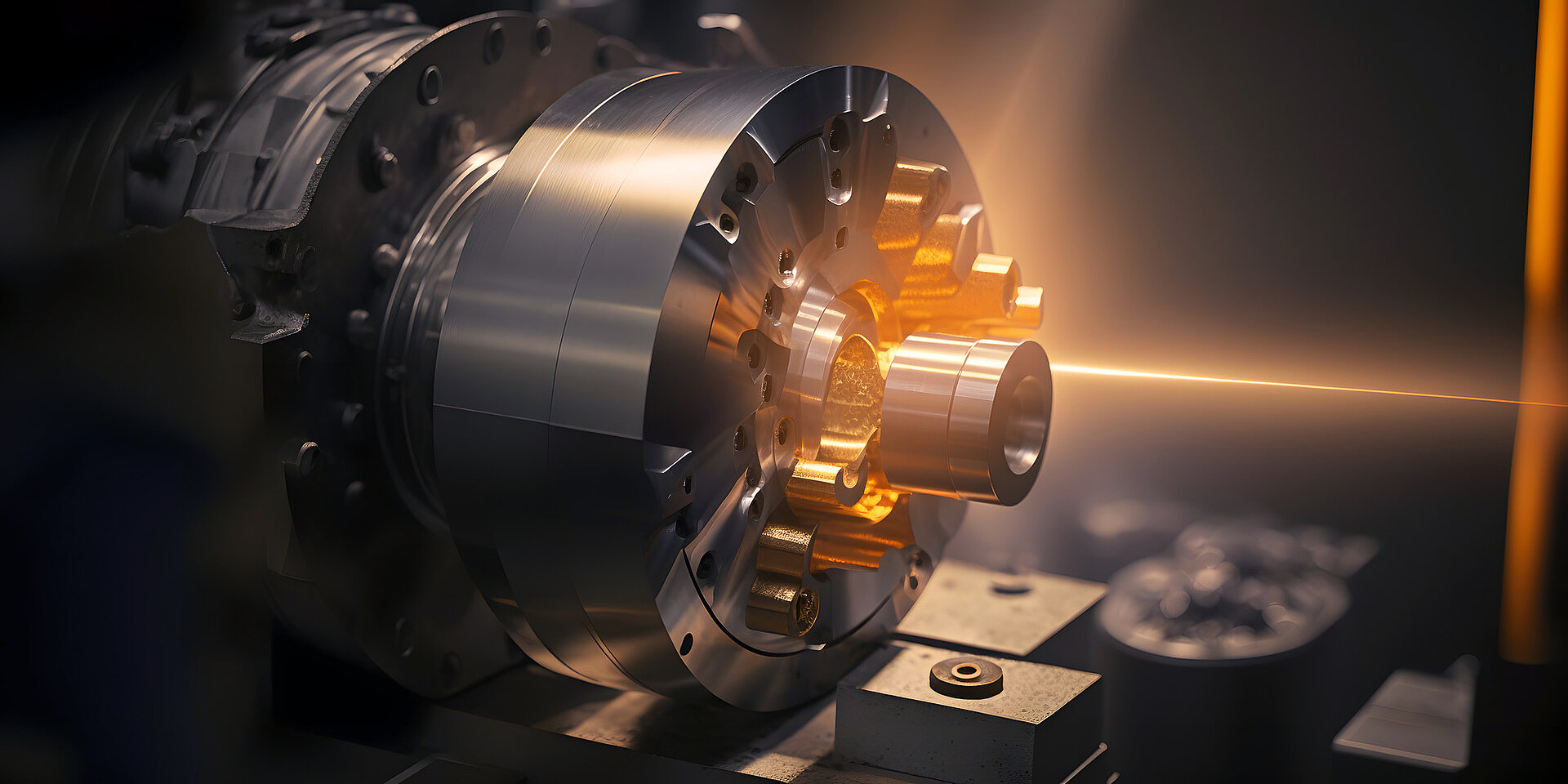

Hardness

In areas of application where components are exposed to high mechanical loads, such as in machining, as sliding partners in ceramic joint replacements, in mechanical engineering or in pump, valve and seal technology (PVS), high mechanical properties such as hardness and strength of technical ceramics extend their service life.

Compared to conventional metals and plastics, technical ceramics set standards in terms of robustness and performance.

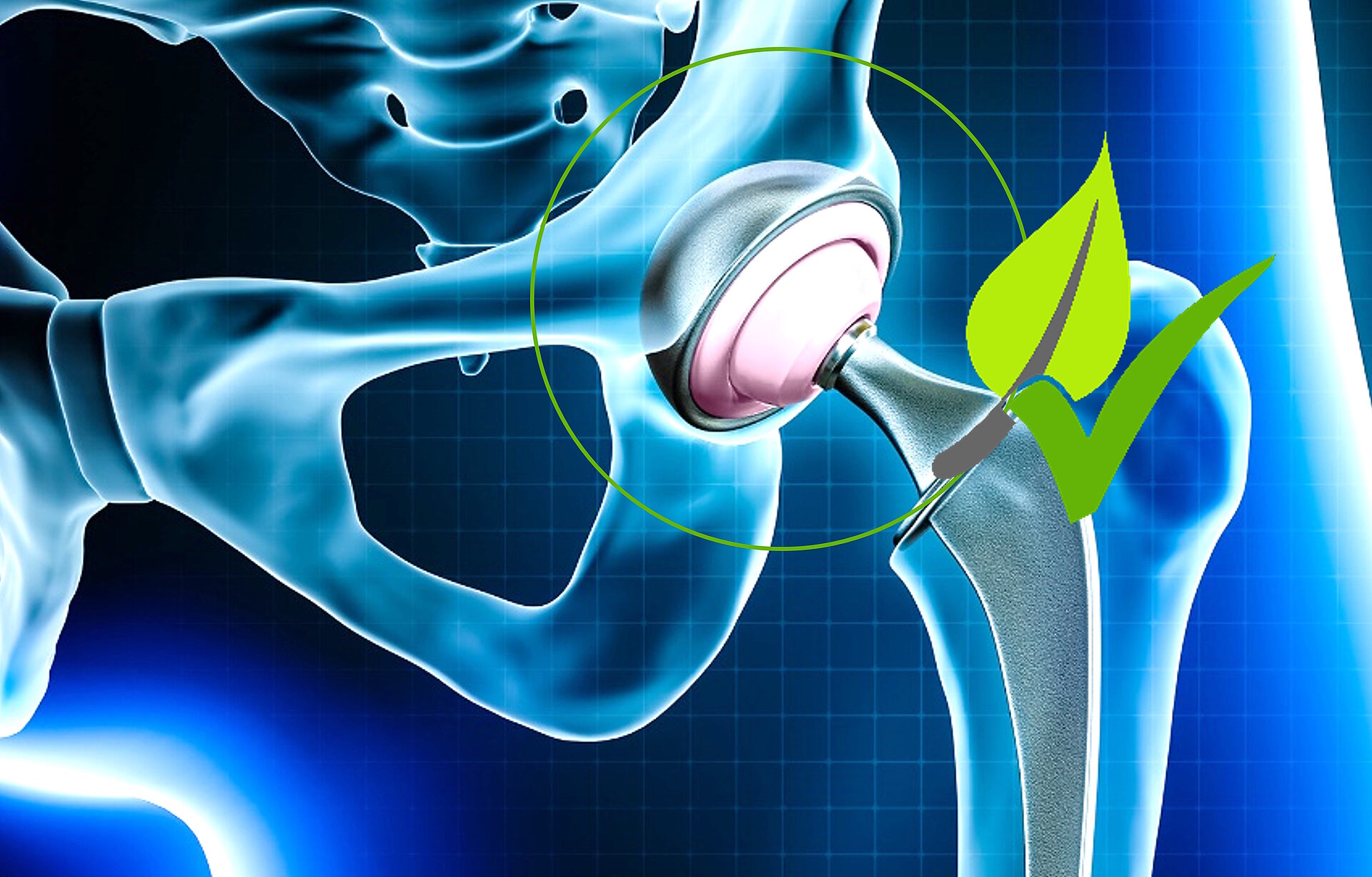

Biocompatibility

Technical ceramics are wear-resistant, durable and often chemically inert, which means they do not react to body fluids or chemicals. In contrast, some metals can corrode or cause chemical reactions in the body, while plastics can degrade. In addition, the smooth surface of bioceramics makes it difficult for bacteria to adhere, while micro-cracks or pores can form in metals and plastics, favouring bacterial growth.

Their exceptional mechanical properties, chemical inertness and minimal interaction with biological systems make technical ceramics the preferred material for medical implants and prostheses.

Piezoelectricity

Piezoelectric ceramics have unique properties that enable seamless integration into numerous modern technologies - from ultrasonic transducers in medical devices to piezoceramic sensors in automotive technology.

Piezoelectric ceramics are used to convert mechanical quantities such as pressure and acceleration into electrical quantities or, conversely, electrical signals into mechanical movements or vibrations.

Superior Performance of Ceramics* vs. common Materials

| Material Properties | Ceramics | Metal | Polymers |

| Biocompatibility | + | - | o |

| Hardness | + | - | - |

| Wear Resistance | + | - | - |

| Density / Weight | + | - | + |

| Dimensional Stability | + | - | - |

| Chemical Resistance | + | - | - |

| High Temperature Resistance | + | o | - |

*Properties may vary accordiung to the ceramic material being used