Careers at CeramTec

You want to make a difference, are enthusiastic about exciting projects and are looking for a dynamic team with great people? At CeramTec we offer you and your career an attractive environment! Whether as a skilled worker in our production, as a manager at one of our numerous locations or in our administrative departments - the diversity of the CeramTec world opens up opportunities! Career changers are also welcome here.

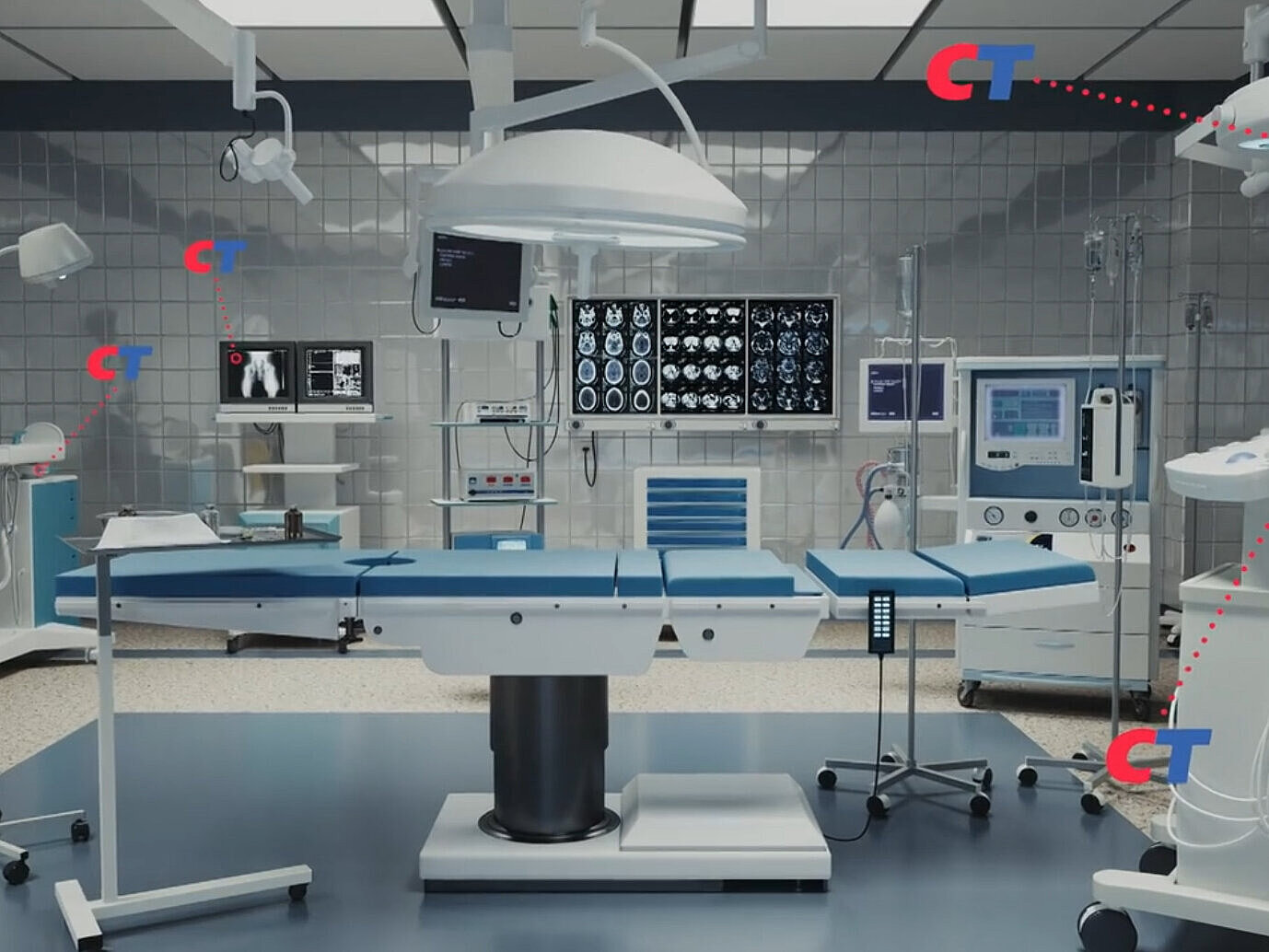

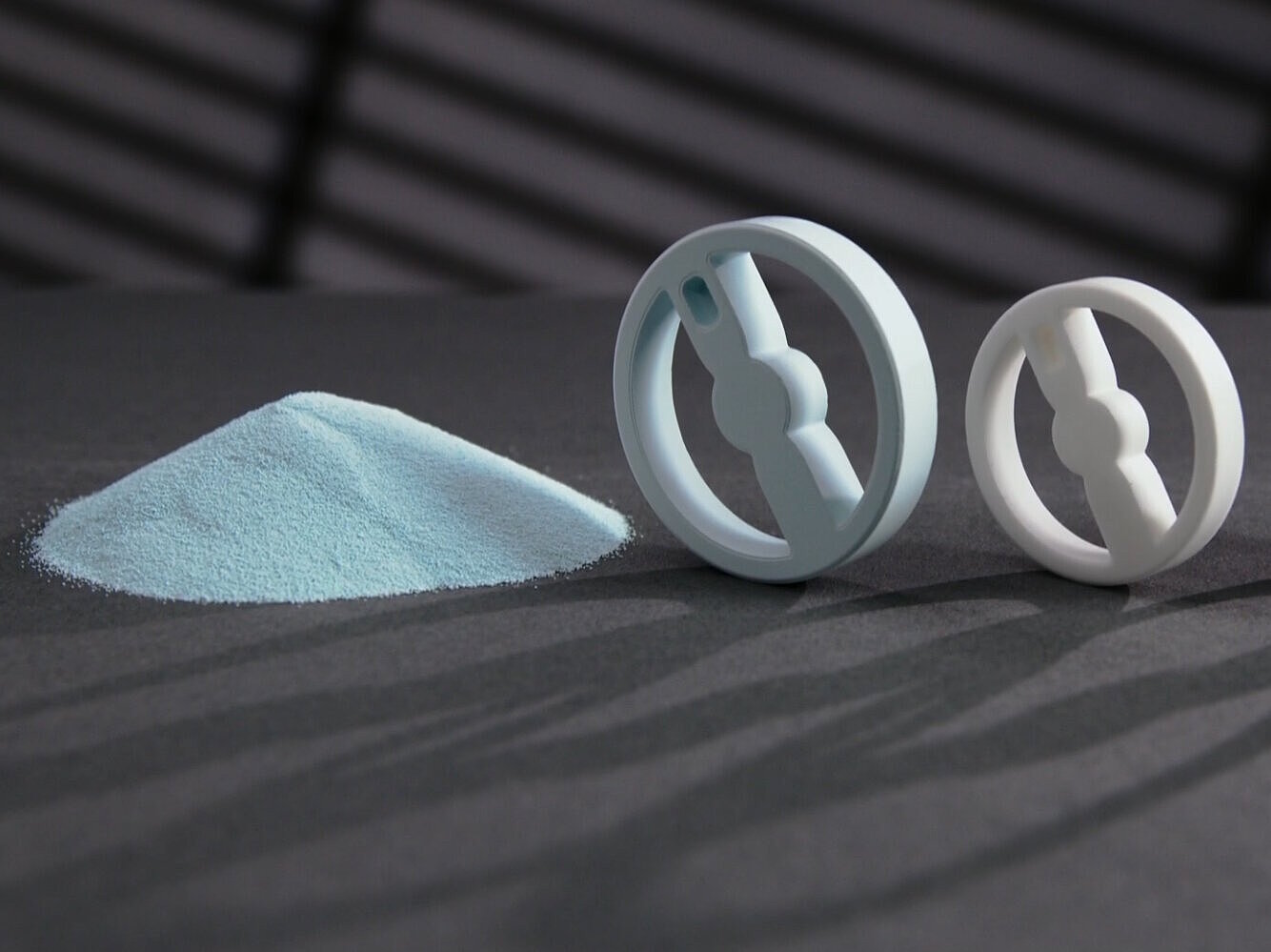

With its many favourable properties, advanced ceramics is a fascinating material that is used in medical technology and numerous future-oriented industrial sectors.

CeramTec colleagues work on a variety of interesting tasks in different projects and a range of more than 10,000 products and solutions. Whether in research and development, in production in controlling or in another of the many different departments: Varied activities can be found everywhere at CeramTec. Together we shape the future! To this end, we are constantly looking for motivated employees.

Your Contact Persons on Site

CeramTec-Platz 1–9

73207 Plochingen

Luitpoldstraße 15

91207 Lauf

CeramTec-Weg 1

95615 Marktredwitz

An der Burg Sülz 17

53797 Lohmar

Antelope Park, Bursledon Road

Thornhill, Southampton

Hampshire, SO19 7TG

Vauxhall Industrial Estate

Ruabon, Wrexham

LL14 6HY

Zerotinova 62

78701 Sumperk

One Technology Place

Laurens, SC 29360