Piezoceramic power converters are convincing in the production of medical protective masks

The use of protective masks in public places for the mutual protection of infections with the COVID-19 virus is intensively and controversially discussed worldwide. However, the special protection of these masks in the medical field and especially in the treatment of COVID-19 patients is beyond question.

Reliable and stable components and parts play a crucial role in such a highly cyclical production process. For the industrial production of such masks, even for very large quantities, ultrasonic welding machines are used to produce the hem of the masks and join multiple layers.

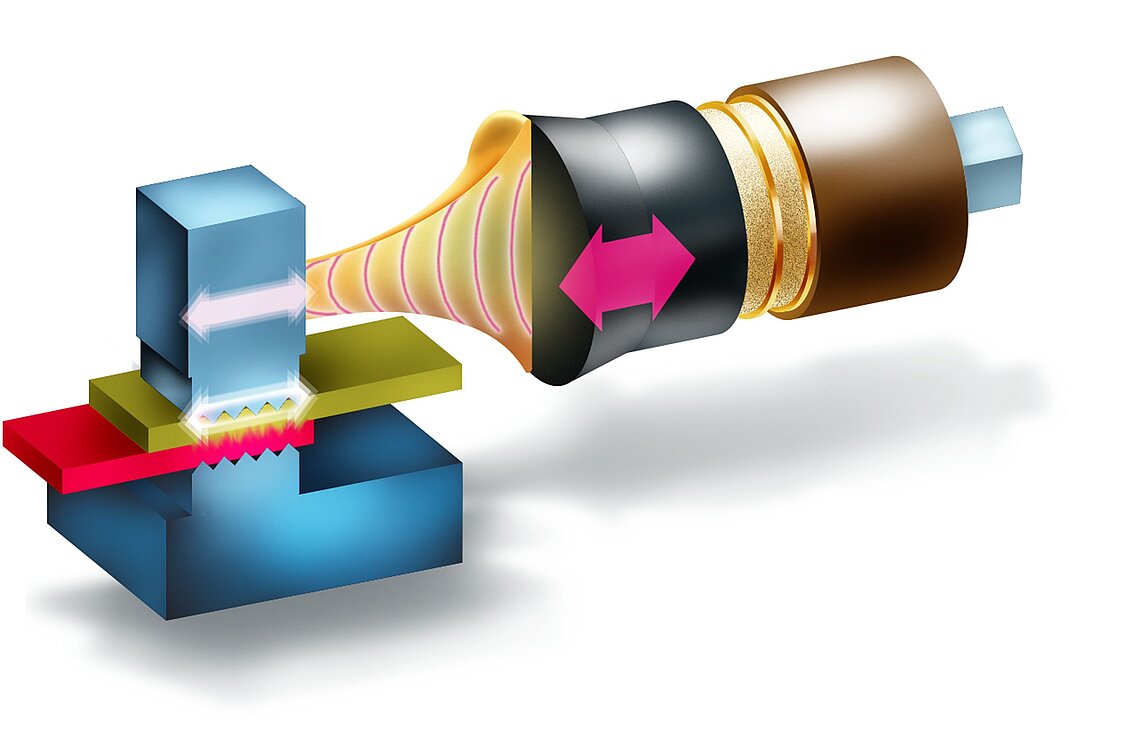

Piezoceramic power transducers are core components of ultrasonic welding equipment used in the production of the seam. Ultrasonic welding uses the frictional energy generated by the ultra-sound at the interfaces of the materials to be joined. If two moulded parts are pressed together at their joint surfaces and excited with high-frequency ultrasound, their joint surfaces fuse together. This works with some metal parts as well as with plastic parts including artificial fibers as often also wires are inserted into the seam in order to be able to adapt the masks to the facial contours and thus further increase the protective performance.

The ultrasonic energy is supplied to the materials to be joined via a so-called sonotrode. The sonotrode amplifies the ultrasound generated by the piezo composite oscillator. The piezo composite oscillator is made up of two or more piezoceramic rings which are clamped together by means of metal end pieces.

These rings are made of piezoceramic materials and play the main role in the ultrasonic welding process. CeramTec’s low loss materials and tolerances ensure maximum efficiency of process by minimizing mechanical and electrical losses in the transducer and system.

Do you have any questions or need more information? Then please contact the CeramTec Corporate Communications department at pr@ceramtec.de.