Saltcore Technology

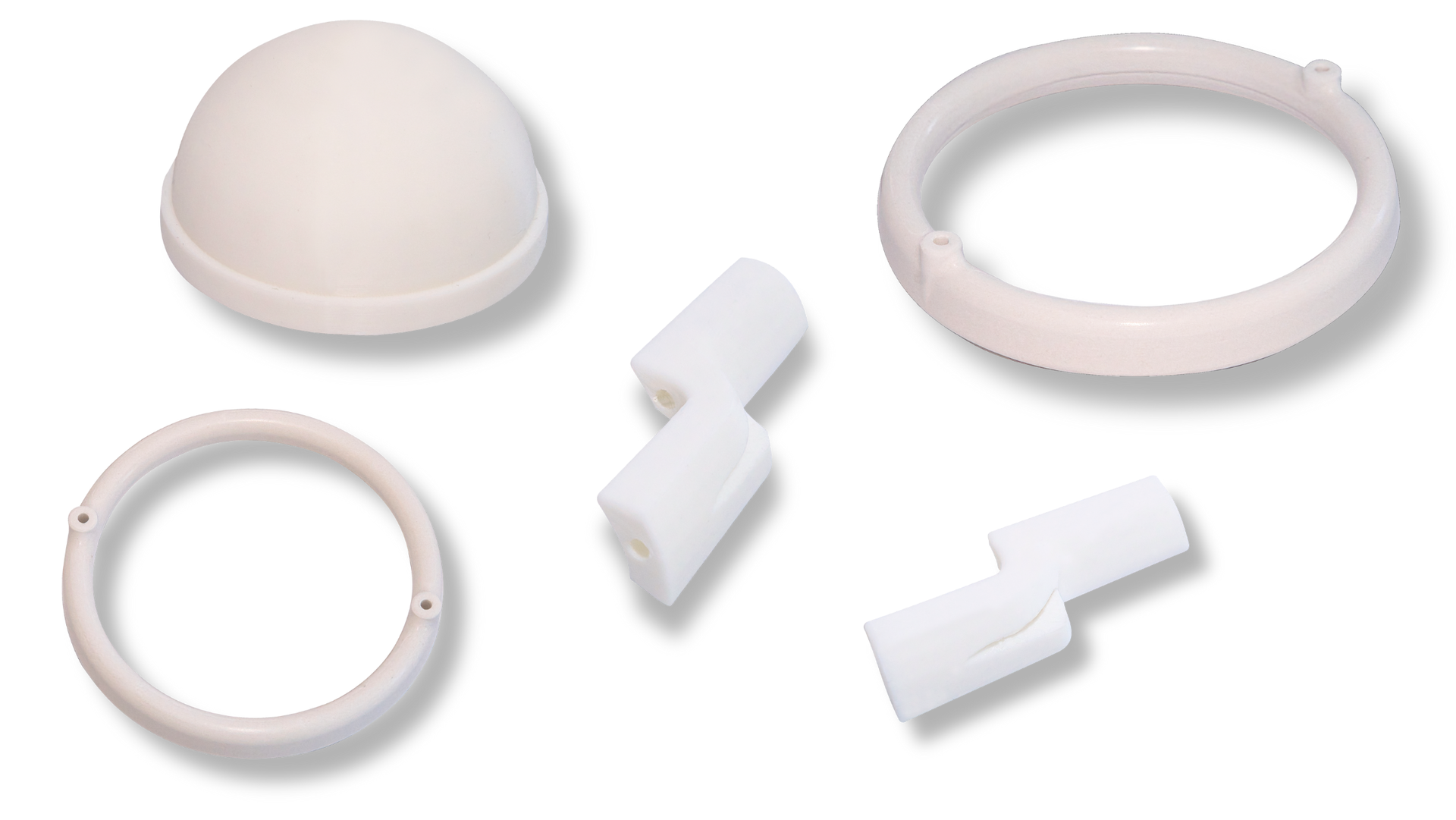

Our advanced saltcores are used in various die casting processes - from low to high pressure, gravity casting to modern applications in thixomoulding and injection moulding. Compared to classic sand cores, our NaCl cores made from natural and pure raw materials impress with a simple, clean and residue-free rinsing process.

We solve complex undercuts and internal cavities with our EMG saltcore technology.

The proven EMG saltcore technology enables precise solutions for demanding geometries during moulding. Thanks to their high temperature resistance and minimal post-processing effort, our saltcores make a decisive contribution to reducing the complexity of components and moulds. They are produced using our tried-and-tested single-axis pressing process and are ideal for various alloys such as magnesium and even plastics.

For further information on our capabilities and award winning saltcore solutions, please use our contact form or call us on +49 910 29935-0.

Advantages for your Casting Process

- Extended design freedom

- Internal contours and cavities can be represented in the cast component

- Elimination of complex slider technology

- Near-net-shape production: no post-processing of the end product necessary

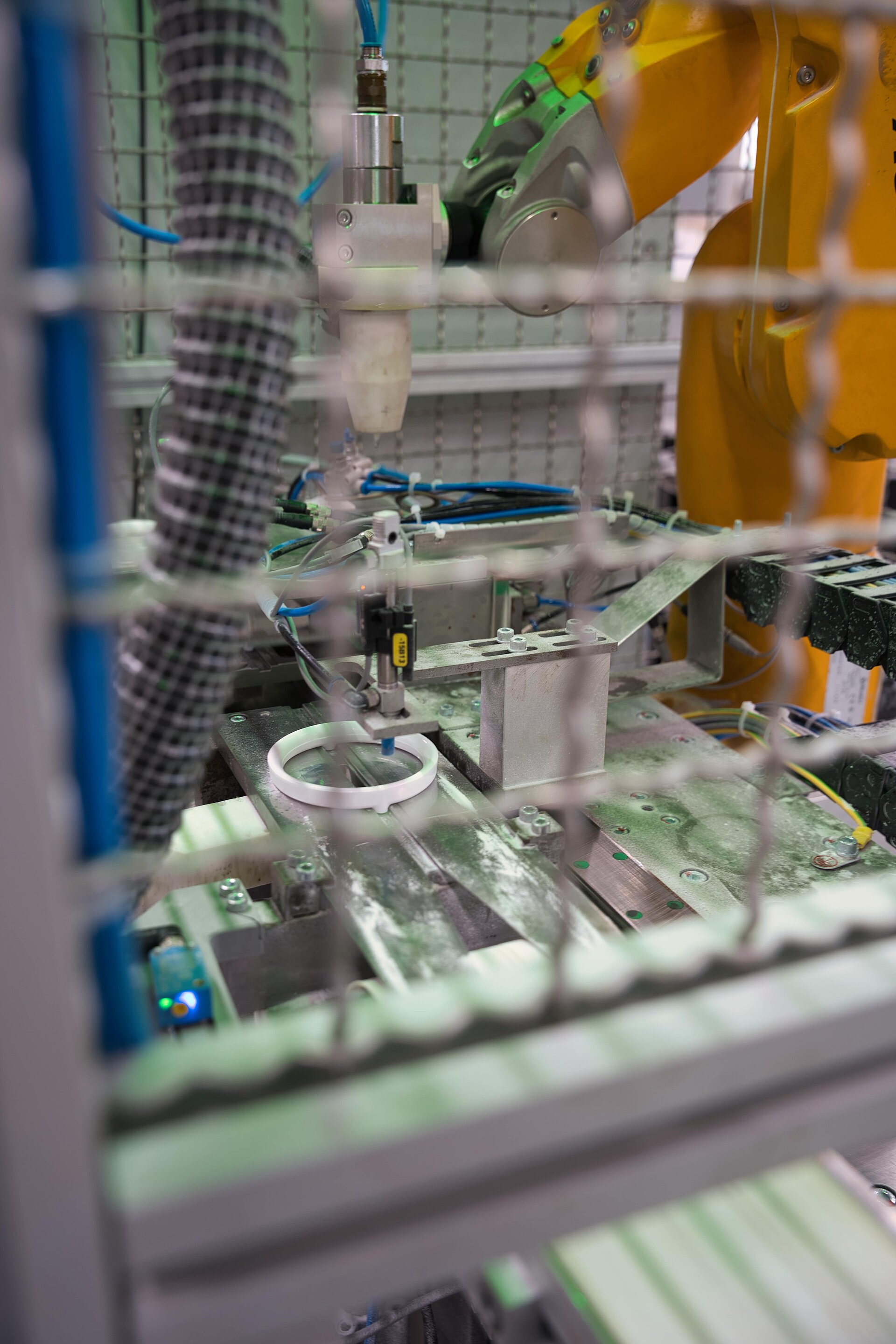

- Can be used under automated, harsh conditions and even in die casting

- Residue-free and gentle saltcore removal

Brochure: Saltcore Technology

EMG by CeramTec

Emil Müller GmbH was founded in 1921 and has been manufacturing saltcores for more than 40 years. Producing in excess of 20 million saltcores per year, EMG has proven to be a reliable supplier of complex saltcore geometries for customer specific applications worldwide.

Headquartered in Wilhermsdorf, Germany, EMG by Ceramtec employs 150 in its five manufacturing facilities in Germany, Poland, Mexico, India and Brasil.

CeramTec India Innovative Ceramic Engineering Pvt. Ltd.

Plot No. C-192, Industrial Focal Point - Patiala - Punjab - 147004

Mr. Lakhwinder Singh

Phone: +91 (0) 90412-85918

PST - Press Sintertécnica Brasil Importação Exportação LTDA

Rodovia Arnaldo Júlio Mauerberg 3960 - Pq Ind. Tânia Maria Covalenco, Prédio 05 - Nova Odessa - SP - CEP 13388-090 - Estado de São Paulo, Brasil

Mrs. Sandra Cibin

Phone: +55 193498-1282

Press and Sinter Technics de Mexico, S.A. de C.V.

Resurrección Oriente 10 - Parque Industrial Resurrección - C.P. 72228 Puebla, Pue. - Mexico

Mrs. Alma Perez

Phone: +52 222 2229380

PST Press + Sintertechnik Sp.z.o.o.

Ul. Odlewnikow 52 - PL 39-432 Gorzyce - Poland

Mrs. Edyta Jarosz

Phone: +48 15836-0605