Advanced Ceramic Solutions in New Dimensions thanks to Additive Manufacturing

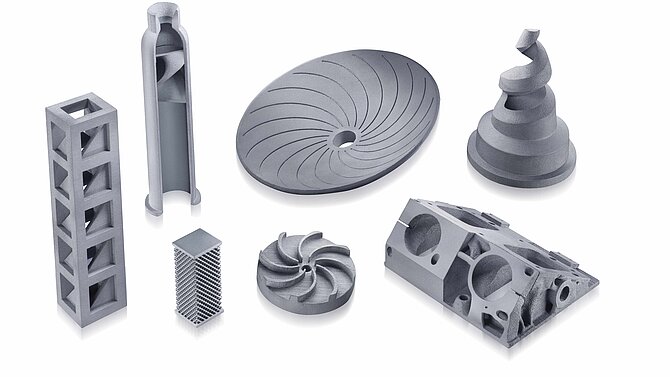

Additive Manufacturing with SiSiC and Al2O3

CeramTec combines the unique material properties of advanced ceramics with the unbeatable process advantages of 3D printing. This is how high-quality, additively manufactured components made of silicon carbide (SiSiC) and aluminium oxide (Al2O3) are created - in a wide variety of designs and in the shortest possible production times.

- Print directly from CAD data

- No tools required

- Cavities and undercuts possible

- Short production lead and tooling

- Maximum flexibility: design changes at the click of a mouse

- Digitisation of existing components possible

- Simultaneous production of several components on one 3D printer possible

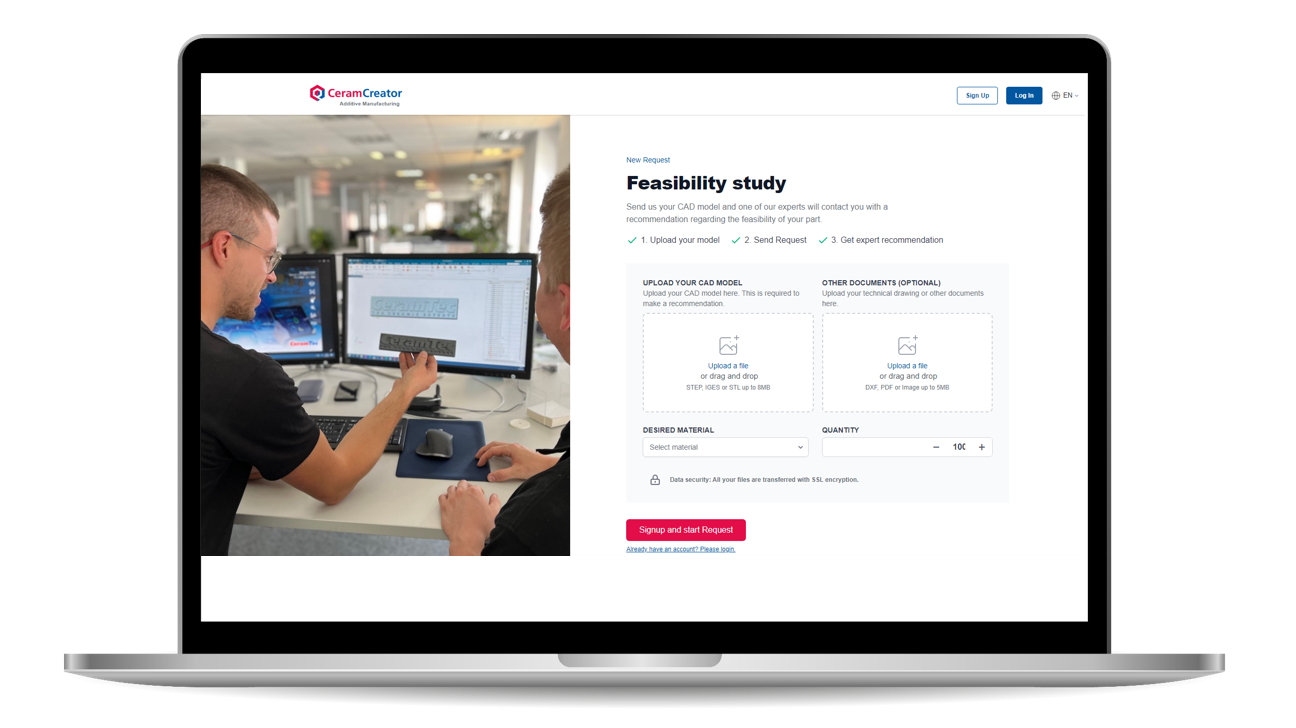

Our competent service team supports you in product development - from the idea to the finished product.

CT Top DownloadsIndustrial Applications

3D Printing - Additive Manufacturing with SiSiC and Al2O3

Advanced ceramics from batch size 1 – individually designed additive manufacturing with silicon carbide and aluminium oxide

Download